Sectors

Accuturn has over 10 years experience in machining precision components for the medical, automotive, motorsport and construction sectors providing CNC Turning and Milling.

The company prides itself in innovation and working in long term partnerships with their customers. They have experience of working alongside R&D teams to redesign products to improve production techniques, product design and produce a higher quality end product with less time and cost.

Automotive

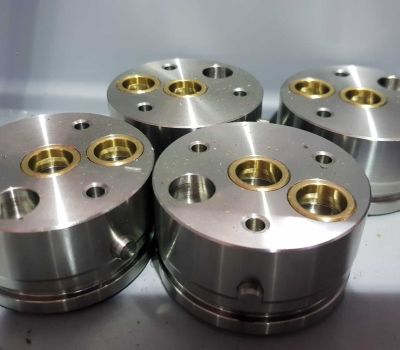

Accuturn have manufactured a range of components for the automotive and motorsport industries including clients’ bespoke wheel hubs.

Our lean manufacturing practices lend themselves to the automotive industries just-in-time processes with an emphasis on providing on-time deliveries.

We have the capabilities to manufacture large batches of complex components with lights out machining.

Construction

Accuturn manufacture various components with a very high-quality finish, removing the need for additional post machining operations such as polishing, with experience of producing components such as handrails, balustrade connectors and taps for high specification projects.

Other components including filter cartridge housings and larger scale filtration products and systems for the UK and overseas market.

Accuturn have collaborated with clients on design and manufacturing to make changes to the design which have led to a simpler and more cost-effective production process.

Medical

Accuturn’s team have over 20 years’ experience of manufacturing components for safety critical devices for the medical industry sector. Some examples would include components for lung simulators, medical gas hoses, gas probes and gas scavenging systems.

Accuturn can provide certificates of conformity with systems operating in line with ISO9001 and ISO14001 standards.