The 8 Wastes of Lean- what does that mean?

We’ve finished our big 3S sort out but we’re very conscious that having super organised shelving is only one part of the bigger Lean picture. So we can’t just stop here! 3s has helped us set the foundations in the assembly department but now it’s time to start building on them. It’s put us in a good position to start evaluating our processes but before that, we need to be really aware of what factors might be affecting our ability to operate at our full potential. And that is where recognising The 8 Wastes of Lean can help us.

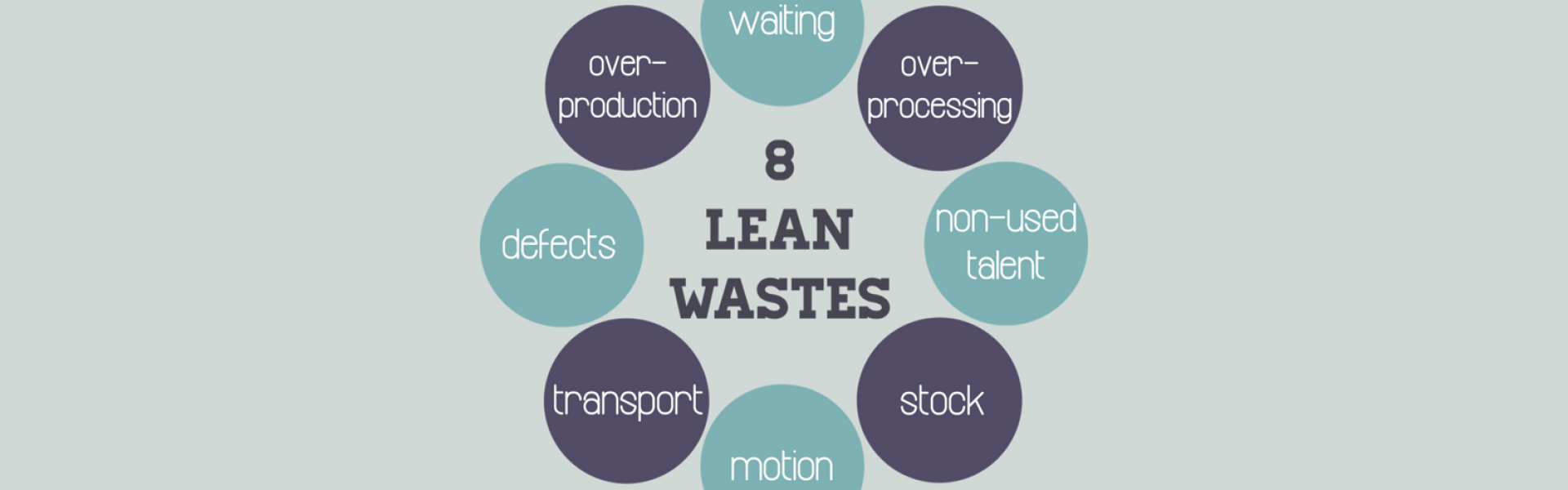

What are The 8 Wastes of Lean?

In a nutshell, waste is all the unnecessary things, big or small, that occur during the working day that are not adding any value to your products or processes. The 8 Wastes of Lean is a really handy tool for helping you to hi-light the main problem areas. These are as follows:

Overproduction– producing too much and before you actually need it

Transport– unnecessary movement of parts and materials

Motion– you personally (and your staff) moving around far more than is necessary

Waiting– this could be on suppliers, parts to be processed by another department, on someone with the right skills to complete a particular task… the list is exhaustive

Over Processing- extra and unnecessary procedures which don’t actually add any value to what you’re doing

Stock- too much raw material or stock sitting on shelves that aren’t being used

Defects- time spent reworking faulty parts, taking you away from other productive tasks

Non-used Talent- employees not being used to their full potential

Applying The 8 Wastes of Lean at Stokes & Rowe

Rather than sitting and trying to think of all the wastes that are occurring on the shop floor, we decided the best approach would be to get out there and try to recognise The 8 Wastes of Lean as we’re doing each job. It was amazing (and pretty scary!) to see how much waste we actually had and how we had just been taking so many processes for granted! Silly things like parts we regularly use during tap assembly being on the shelf behind meant we kept turning and reaching for them. Why not organise the assembly cell a little better to incorporate it onto the bench in front of us! It had just always been like that and no one had thought to question it (Motion).

during tap assembly being on the shelf behind meant we kept turning and reaching for them. Why not organise the assembly cell a little better to incorporate it onto the bench in front of us! It had just always been like that and no one had thought to question it (Motion).

We test every single tap that leaves our factory so that we are 100% confident with every one we send out. Previously we might have around 10 taps at the end of the month that required reworking (Defects). By working closely with the machine shop we reduced that to two this month. We’re aiming for zero defects on our next assembly by having 100% inspection of every single component as it comes off the machine.

We’ve also found that including our staff has been absolutely invaluable to the process. They have had so many ideas, but we’d just never asked them before! (Non-used Talent).

Has it helped?

It has been a revelation to see the impact that being aware of The 8 Wastes of Lean has had on us all! Now everywhere we look, we just keep seeing waste! We have learnt that even just a couple of seconds of waste per process can add up to an extra 30 minutes, an hour or more over the whole working day!

Happy Manufacturing!

Rob, Nicola and the Team