3S – Sweep, Sort, Standardise

Back in January we made our big announcement about ‘Going Lean in 2017!’ but then we were faced with the dilemma of where to actually start! We’ve got a factory incorporating offices, machine shop and an assembly department and standing out there on day one, I’ll admit, left us feeling pretty overwhelmed! So we went to the drawing board to review the various LEAN techniques that we were keen to have a look at this year. 3S jumped out at us- short and sweet! And we decided to start out in the assembly department.

But what does 3S actually mean?

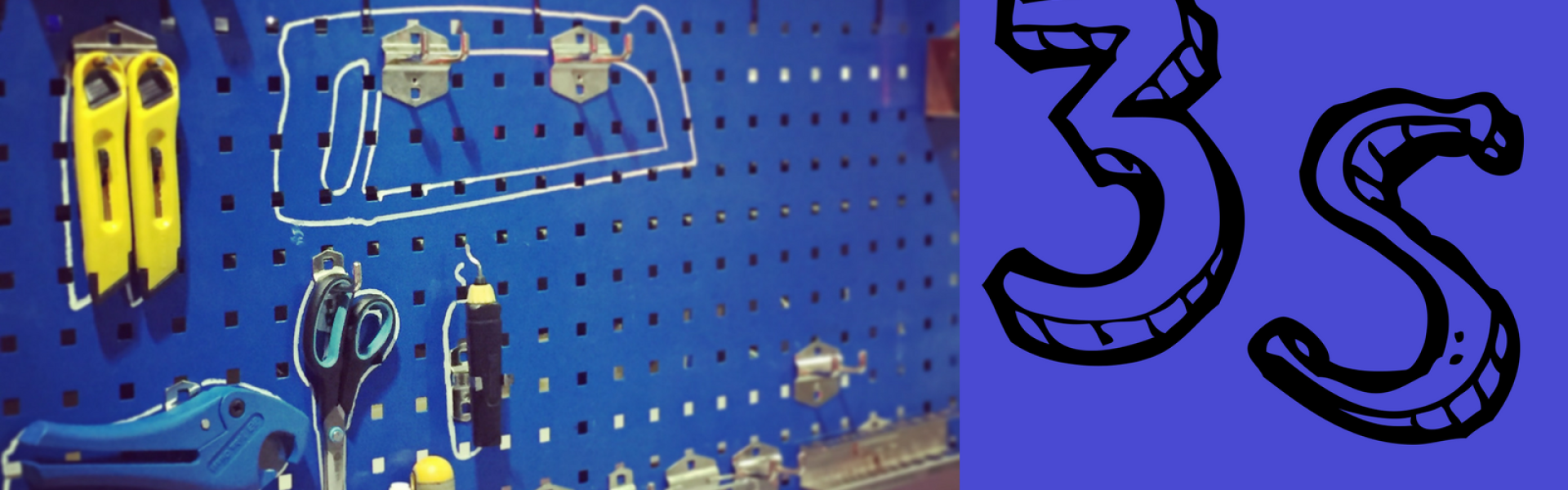

3S stands for Sweep, Sort and Standardise. So in layman’s terms, for us it was about having a clean and tidy up (Sweep), whilst sorting through all our tooling and equipment. This meant creating a set place for tools that are used on a regular basis, rehoming tools that shouldn’t really be there, binning what wasn’t necessary and creating a holding area for items which need to be reviewed (Sort). Magnetic labels have become our new best friend as every item we manufacture ready for assembly has been given its set place and a simple bit of tipex on a louvre panel means there’ll be no more hunting around for the scissors! This exercise was about setting a minimum standard for how the assembly department should look and function (Standardise).

labels have become our new best friend as every item we manufacture ready for assembly has been given its set place and a simple bit of tipex on a louvre panel means there’ll be no more hunting around for the scissors! This exercise was about setting a minimum standard for how the assembly department should look and function (Standardise).

We made sure that our team were completely involved with the whole process, (which only actually took a couple of days to completely transform the assembly department)! They feel totally invested in the changes we are making and can see how it is going to make their working day easier and more enjoyable. We were blown away by the fantastic ideas they had!

So now we need to see if we can Sustain it… (that’s another S in there for you)!

Happy Manufacturing!

Rob, Nicola and the team